Turning Inserts

Turning Inserts are indexable cutting tools used in lathes and CNC turning centers to shape, cut, and finish cylindrical components. They feature replaceable carbide tips that deliver consistent performance without the need for re-sharpening. In Pakistan, where manufacturing and automotive industries demand efficiency, turning inserts are crucial for high-speed precision machining of metals and alloys.

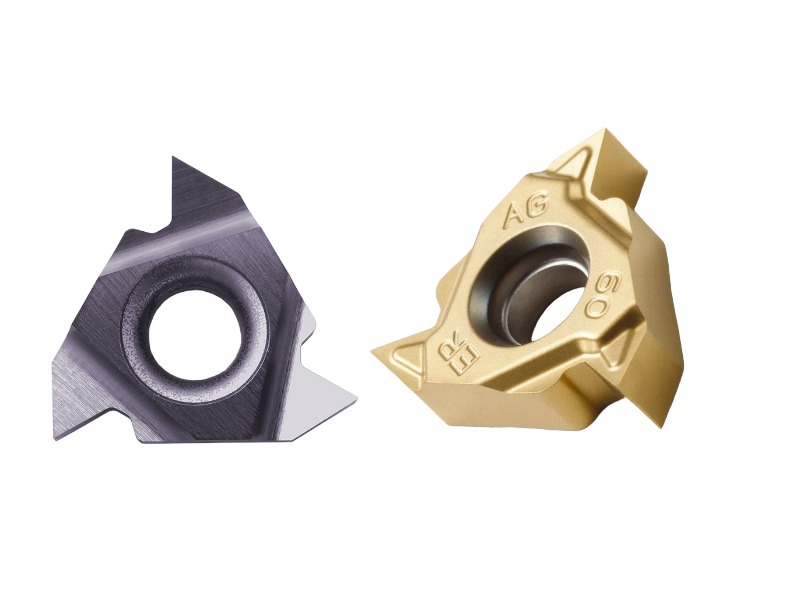

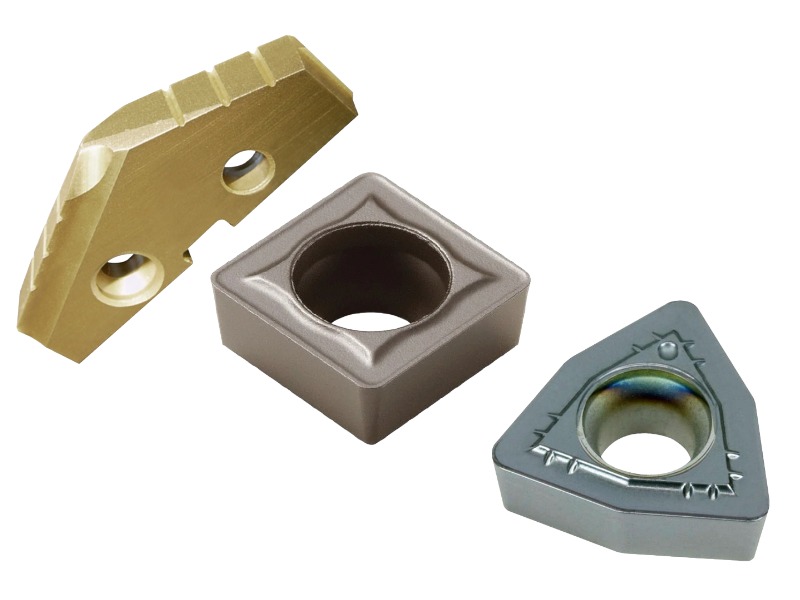

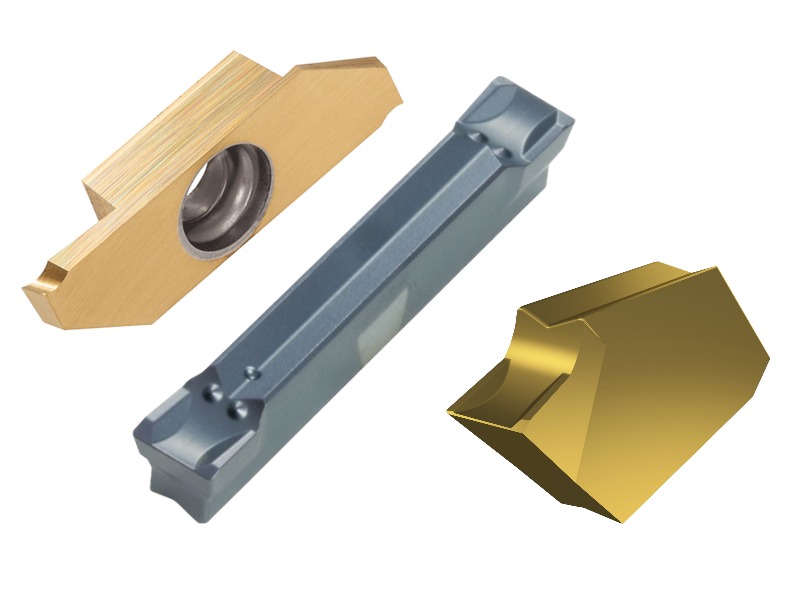

Modern turning inserts are produced in various geometries, including positive rake, negative rake, and chipbreaker designs tailored for specific materials. They are manufactured from carbide, cermet, and ceramic, with advanced coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), and Aluminum Titanium Nitride (AlTiN) to enhance wear resistance and heat stability.

The applications of turning inserts span automotive production, aerospace machining, oil & gas equipment, and general engineering. In Pakistan, manufacturers rely on them for high-precision turning of engine parts, shafts, and hydraulic components.

Performance depends on insert grade, edge geometry, and cutting conditions. High-quality inserts provide excellent surface finishes, reduced cycle times, and longer tool life. Optimizing feeds, speeds, and coolant application ensures efficiency and cost savings in production.

ToolHoo.com offers a complete range of Turning Inserts, from general-purpose carbide tips to high-performance coated grades for CNC machining. With nationwide delivery, trusted brands, and competitive pricing, ToolHoo.com ensures Pakistani industries always have the right solutions for precision turning. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”