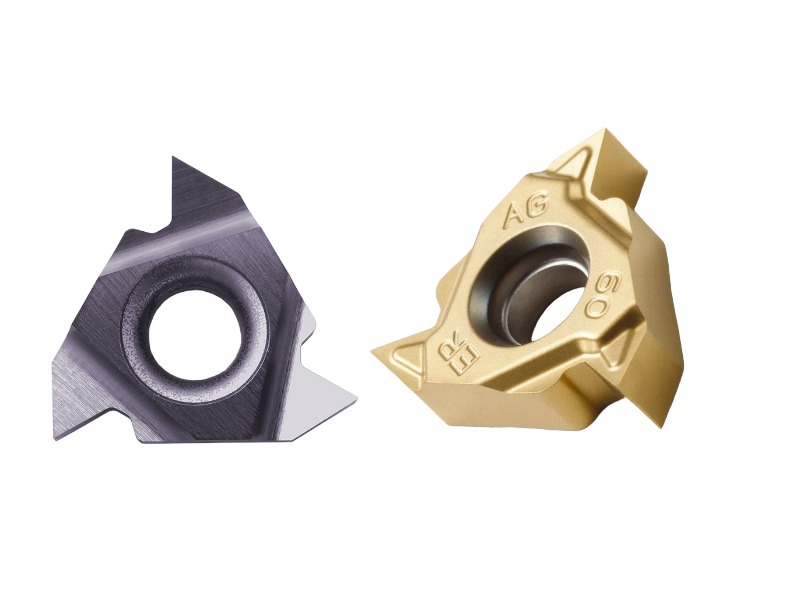

Threading Inserts

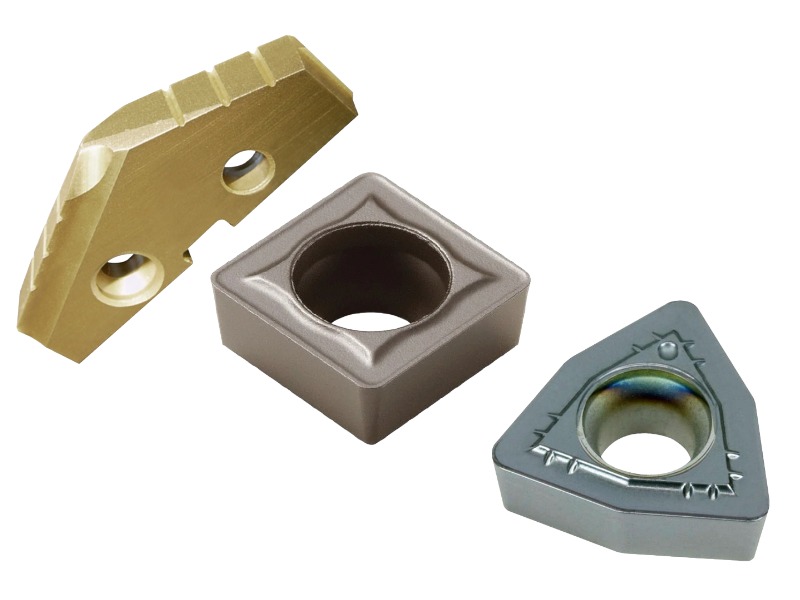

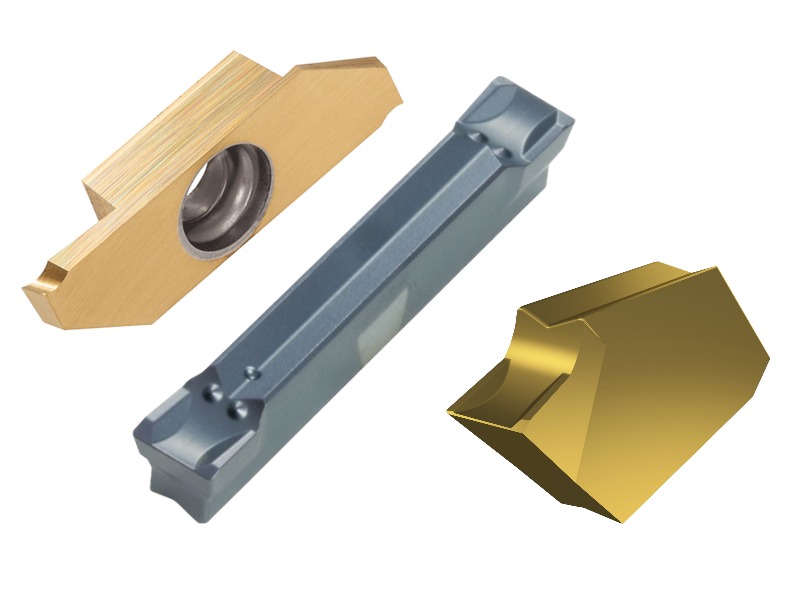

Threading Inserts are indexable cutting tools designed for producing internal and external threads with high accuracy and efficiency. Unlike traditional taps and dies, threading inserts are mounted on tool holders or CNC turning centers, making them ideal for mass production and complex thread profiles. Available in a variety of geometries, pitches, and standards such as ISO, UN, Whitworth, and ACME, these inserts deliver consistent results with excellent surface finish. Their replaceable design allows manufacturers to reduce downtime and cost by simply indexing or replacing worn edges instead of discarding the entire tool.

Modern threading inserts are manufactured from carbide, cermet, ceramic, or CBN substrates, often enhanced with coatings like Titanium Nitride (TiN), Titanium Carbonitride (TiCN), or Aluminum Titanium Nitride (AlTiN). These coatings improve heat resistance, reduce tool wear, and ensure longer tool life even in high-speed threading operations. Depending on the application, inserts are optimized for single-point threading, multi-start threads, or high-precision finishing of cylindrical, tapered, and special threads. Their versatility makes them suitable for both conventional lathes and advanced CNC machines.

The applications of threading inserts extend across critical industries. In automotive manufacturing, they are used for producing threaded engine parts, fastener housings, and transmission components. Aerospace industries depend on threading inserts to create strong, precise threads in titanium alloys and nickel-based superalloys. Oil & gas companies use them to produce threaded pipes and fittings that withstand extreme pressures, while general engineering workshops across Pakistan rely on threading inserts for everything from maintenance parts to custom fabrication.

Choosing the right threading insert involves matching pitch, profile, and grade to the workpiece material. For steel and stainless steel, tougher carbide grades are preferred, while high-performance coatings enhance productivity in hardened alloys. Correct cutting speed, coolant use, and stable machine setup ensure burr-free threads with excellent dimensional accuracy. This makes threading inserts not only efficient but also critical in industries where thread integrity ensures structural strength and safety.

ToolHoo.com, Pakistan’s largest online tool marketplace, provides a complete range of Threading Inserts for both CNC and manual applications. Whether you require inserts for fine-pitch precision threads or heavy-duty oilfield threading, our collection guarantees durability, accuracy, and value. With nationwide delivery and expert support, ToolHoo.com ensures that industries in Karachi, Lahore, Faisalabad, and Islamabad can meet their threading requirements efficiently. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”