Milling Inserts

Milling Inserts are precision-engineered cutting elements designed for use in indexable milling cutters, CNC machining centers, and traditional milling machines. Unlike solid end mills that require full replacement after wear, milling inserts are indexable, allowing operators to rotate or replace only the cutting edge. This not only extends tool life but also significantly reduces machining costs, making inserts a vital part of modern machining processes. Manufactured from high-performance materials such as carbide, cermet, ceramics, and polycrystalline diamond (PCD), milling inserts are capable of handling a wide range of materials including steel, cast iron, aluminum, and high-temperature alloys.

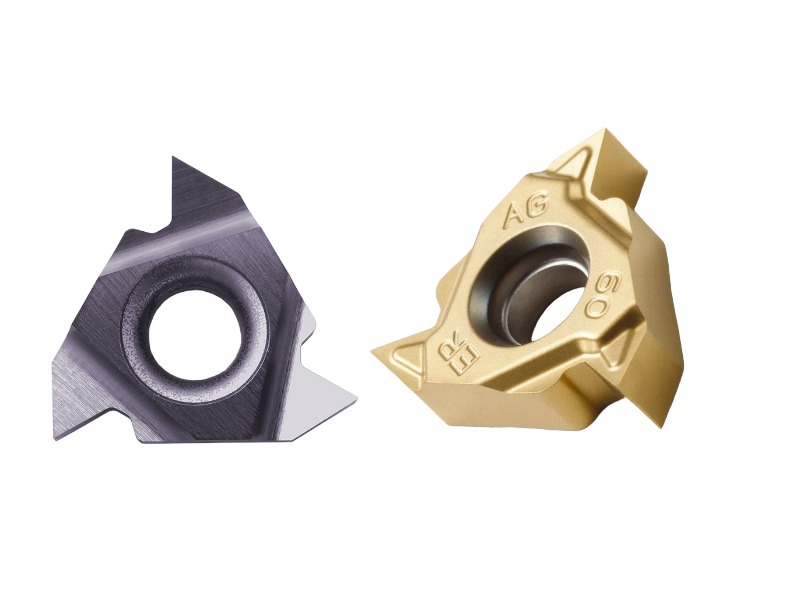

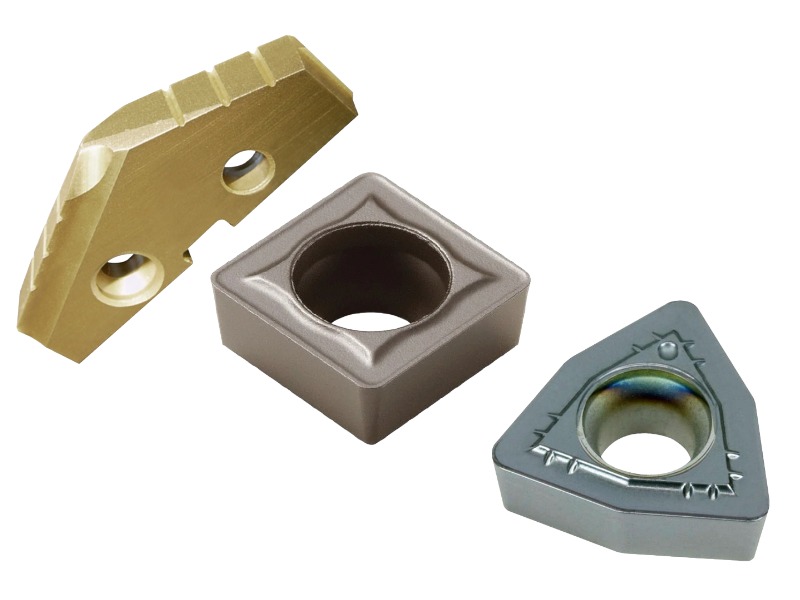

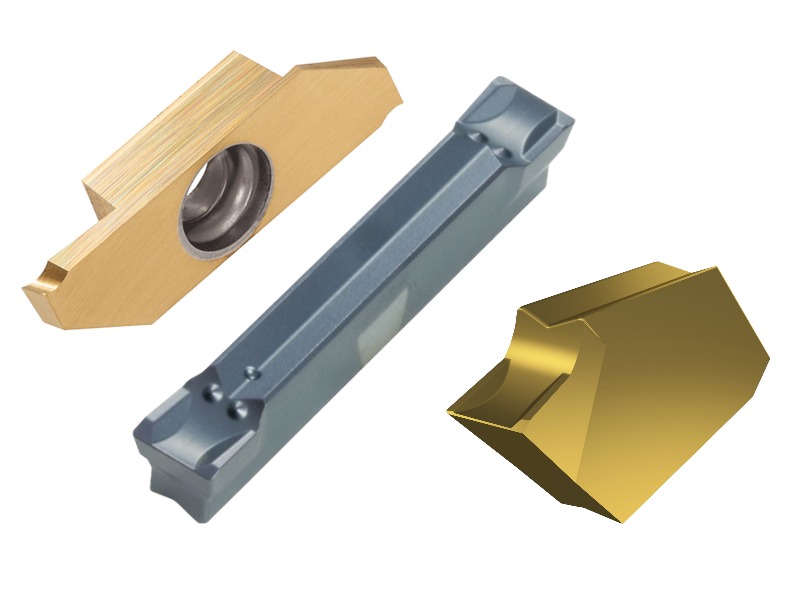

Modern milling inserts are available in various shapes, geometries, and cutting-edge designs to optimize performance. Common shapes include square, round, triangular, and octagonal inserts, each offering different cutting strengths and surface finish qualities. Advanced chipbreaker designs ensure smooth chip evacuation, reducing cutting forces and preventing tool damage. Inserts are also enhanced with premium coatings such as Titanium Nitride (TiN), Titanium Carbonitride (TiCN), Aluminum Titanium Nitride (AlTiN), and Diamond-Like Carbon (DLC), which extend wear resistance, reduce friction, and allow higher cutting speeds. This versatility ensures that milling inserts can be tailored to virtually any industrial requirement, from roughing heavy stock to achieving ultra-fine finishing.

The applications of milling inserts cover a broad spectrum of industries. In automotive manufacturing, they are indispensable for producing engine components, transmission housings, and precision brackets. Aerospace industries rely on carbide and ceramic inserts to machine titanium alloys, Inconel, and composites with extreme precision. Mold and die makers use inserts to achieve complex geometries with high surface finishes, while general engineering and fabrication workshops depend on inserts for efficient machining of structural steels and stainless steels. Even small-scale CNC shops across Pakistan benefit from milling inserts, as they improve productivity and reduce downtime associated with frequent tool changes.

Performance in milling operations depends heavily on selecting the correct insert grade and geometry. Tough grades are suitable for interrupted cuts and difficult-to-machine materials, while harder grades provide longer tool life in stable cutting conditions. Positive rake inserts reduce cutting forces and are ideal for thin-walled parts, whereas negative rake inserts offer stronger cutting edges for heavy-duty roughing. Proper pairing of the insert with machine rigidity, cutting parameters, and coolant application is critical to achieving consistent results. This careful selection and application ensure that industries maximize efficiency, improve surface quality, and extend both tool and machine life.

Economic efficiency is a defining advantage of milling inserts. By replacing only worn edges instead of entire tools, companies significantly reduce tooling expenses. Faster cutting speeds and higher feed rates further enhance throughput, while optimized surface finishes reduce the need for secondary operations such as grinding or polishing. In Pakistan’s competitive machining sector, where manufacturing costs must remain low without compromising quality, milling inserts have become a cornerstone for maintaining productivity and profitability in automotive, aerospace, energy, and heavy engineering industries.

ToolHoo.com, Pakistan’s largest online tool marketplace, offers an extensive selection of Milling Inserts designed for every machining requirement. From roughing inserts for heavy stock removal to high-precision finishing inserts for CNC machining, our range is sourced from globally trusted manufacturers known for innovation and durability. With nationwide availability, expert technical support, and competitive pricing, ToolHoo.com ensures that machinists, engineers, and manufacturers across Karachi, Lahore, Faisalabad, and Islamabad can access the best solutions for their milling operations. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”