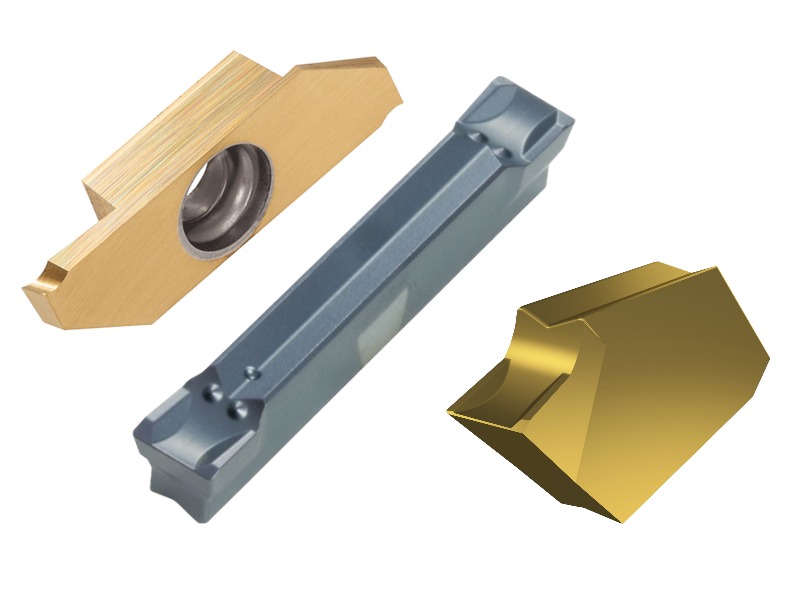

Grooving & Parting Inserts

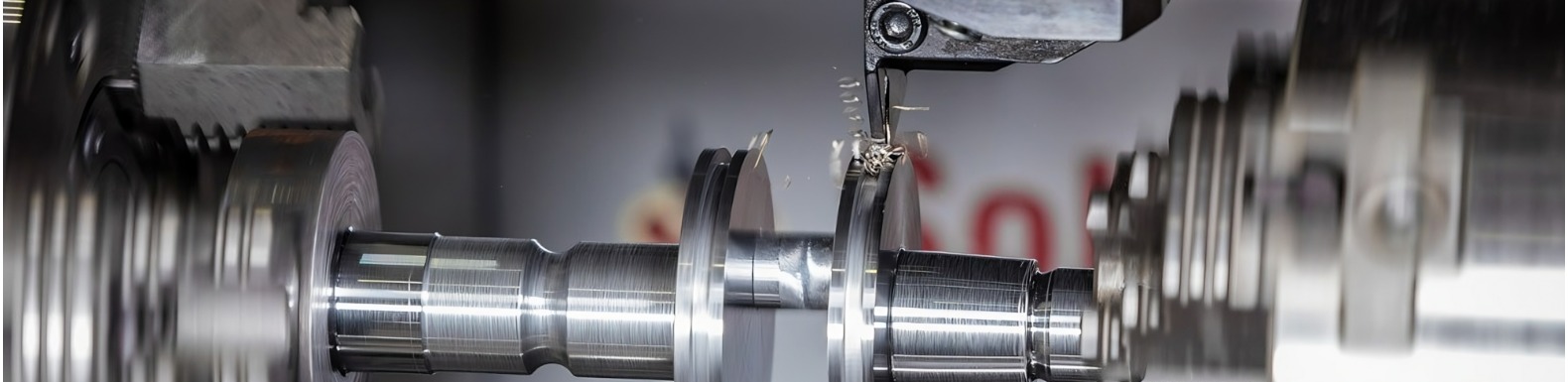

Grooving & Parting Inserts are specialized indexable cutting tools designed for machining grooves and parting-off operations in lathes and CNC machines. These inserts deliver high accuracy in creating precision grooves, slots, and separating workpieces. In Pakistan’s automotive, manufacturing, and maintenance industries, grooving and parting inserts are indispensable for efficiency and precision.

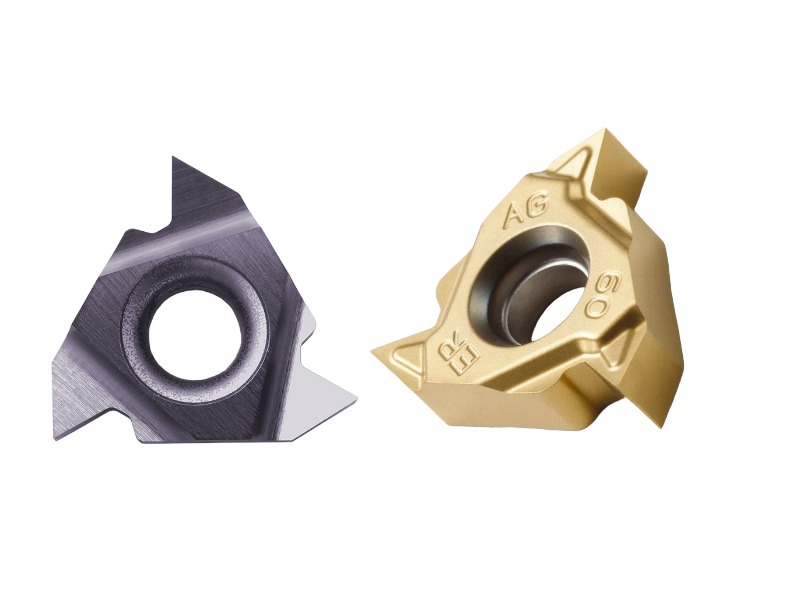

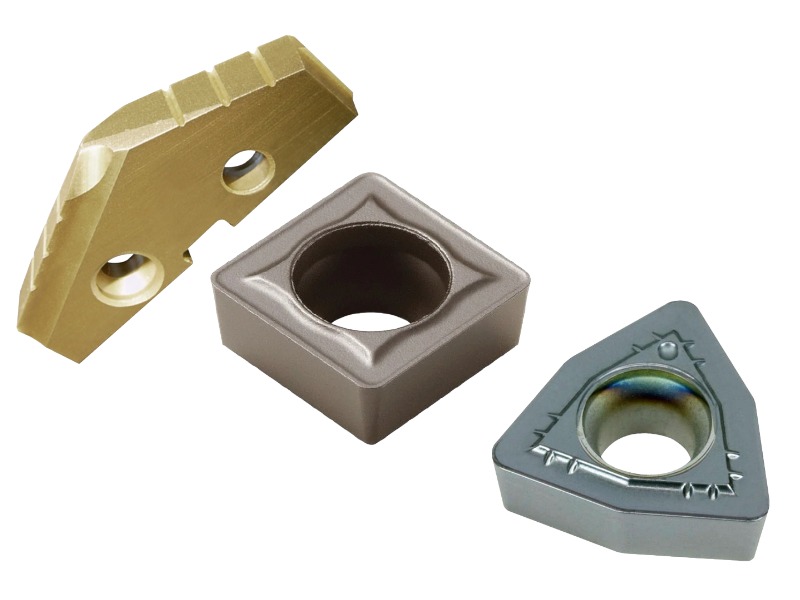

Modern grooving & parting inserts are manufactured from carbide and cermet, featuring chipbreaker geometries and heat-resistant coatings for demanding applications. Available in multiple widths and profiles, they ensure flexibility across different machining tasks. Toolholders are designed for rigid clamping to reduce vibration and improve accuracy.

The applications of grooving & parting inserts span automotive workshops, CNC machining centers, energy industries, and general engineering. In Pakistan, machinists use them for manufacturing circlip grooves, O-ring grooves, and precision component separation in high-volume production.

Performance depends on insert geometry, material grade, and cutting conditions. High-quality inserts ensure clean cuts, minimize burrs, and extend tool life. Proper coolant flow improves chip evacuation and reduces heat buildup, ensuring longer productivity cycles.

ToolHoo.com supplies a wide range of Grooving & Parting Inserts, from economical carbide tips for general workshops to premium coated inserts for CNC mass production. With nationwide delivery, competitive prices, and durable performance, ToolHoo.com ensures Pakistani industries always maintain precision and efficiency. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”