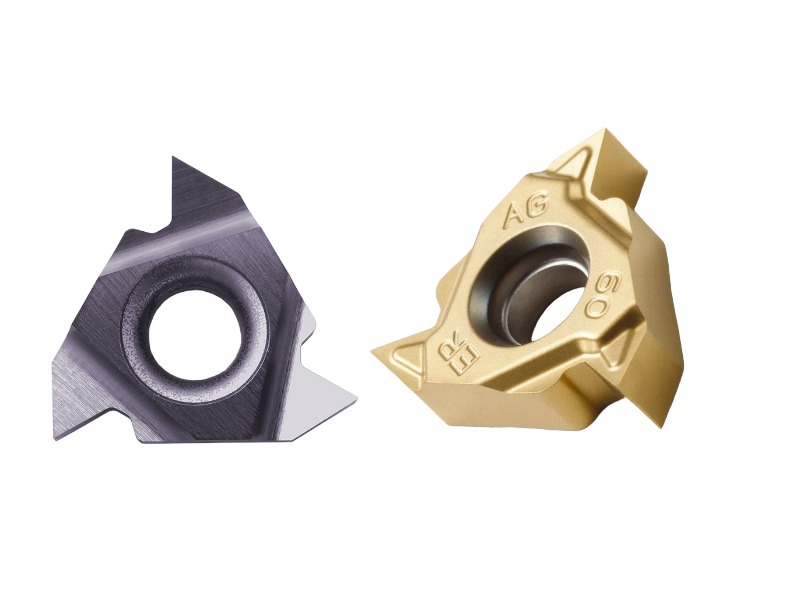

Drilling Inserts

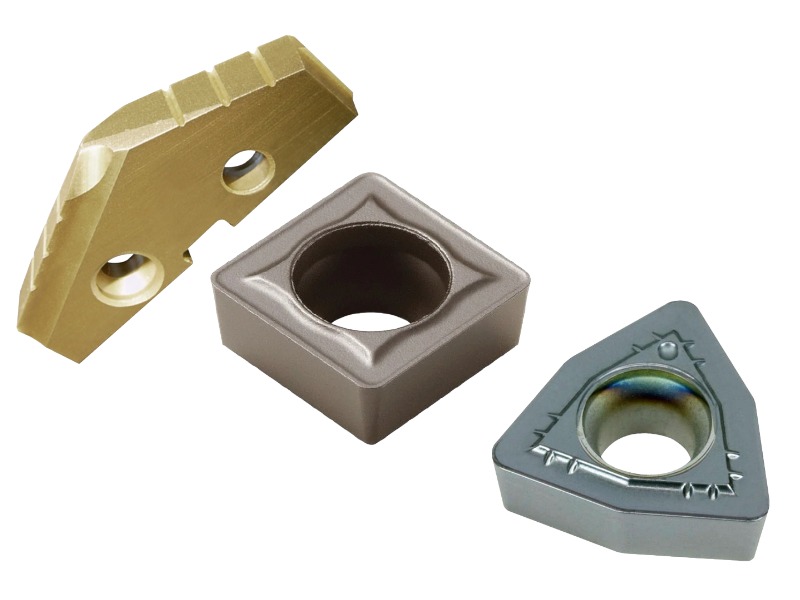

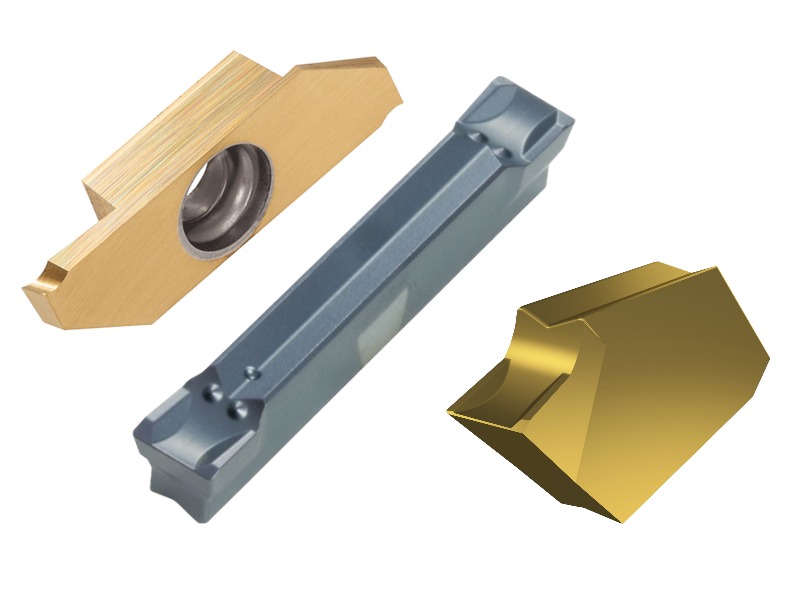

Drilling Inserts are advanced indexable cutting tools used in modular drill bodies and CNC machining centers to create precise, high-quality holes. Unlike solid drills, drilling inserts can be indexed or replaced once worn, significantly reducing tooling costs. They are engineered to handle a variety of materials, including steel, stainless steel, cast iron, and non-ferrous alloys, making them essential for industries that demand flexibility and efficiency in hole-making operations. Their robust design ensures stability and consistent hole quality even under high cutting loads.

Modern drilling inserts are typically manufactured from carbide or cermet and enhanced with coatings such as AlTiN, TiAlN, or diamond-like carbon (DLC) for longer tool life and higher cutting speeds. Advanced geometries improve chip evacuation, minimize cutting forces, and enhance coolant flow, which is especially important in deep-hole drilling. Some inserts are optimized for multi-application use, allowing manufacturers to achieve both roughing and finishing in a single operation.

The applications of drilling inserts span multiple sectors. In automotive manufacturing, they are used for machining engine blocks, crankshafts, and gearbox housings. Aerospace industries employ drilling inserts to machine lightweight alloys and high-strength titanium components with tight tolerances. Heavy machinery and energy sectors rely on them for drilling large structural parts, turbines, and pipeline components. Even smaller CNC workshops benefit from the versatility of drilling inserts, as they reduce downtime and increase productivity.

Efficiency depends on selecting the correct grade and geometry. Positive rake inserts are ideal for softer metals and thin-walled parts, while stronger negative rake inserts excel in high-load drilling operations. Proper cutting parameters, coolant strategies, and machine rigidity are crucial for achieving long tool life and burr-free holes. When applied correctly, drilling inserts can outperform traditional twist drills in both speed and cost-effectiveness.

ToolHoo.com offers a wide selection of Drilling Inserts, ensuring Pakistan’s manufacturers and workshops have access to world-class solutions. From modular indexable drill systems to specialized inserts for high-performance CNC machining, our platform connects industries with the most reliable tooling. With competitive pricing, technical support, and nationwide delivery, ToolHoo.com keeps your drilling operations precise and efficient. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”