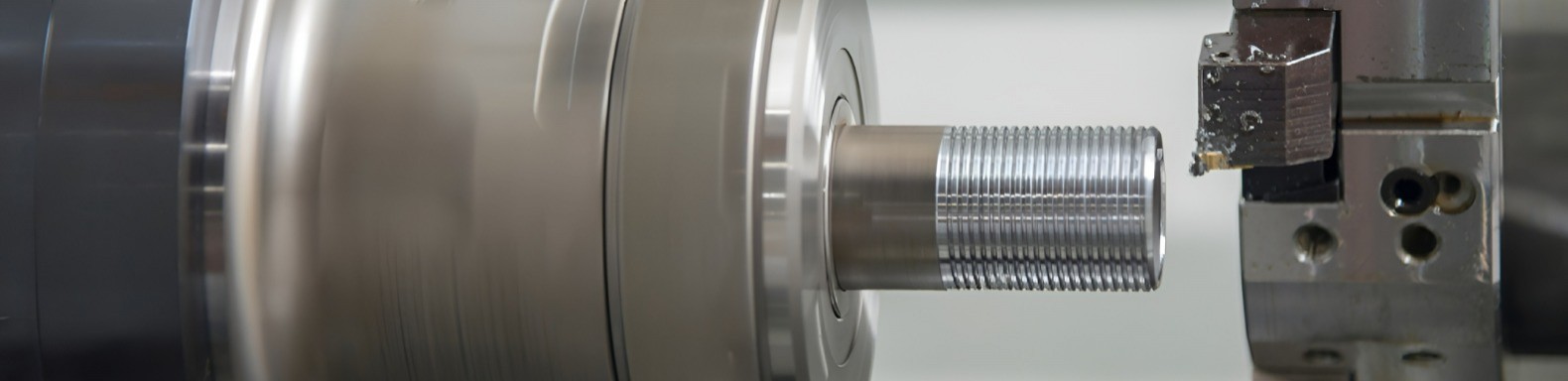

Threading Tool

Threading Tools are specialized cutting instruments used to produce external or internal threads on a workpiece, enabling the secure fastening of components with bolts, nuts, and screws. Precision threading is critical in nearly every sector, from automotive and aerospace to construction and heavy machinery. These tools are available in a wide range of geometries, including solid threading tools, replaceable insert threading tools, and thread mills, each designed to create accurate profiles in various materials such as steel, aluminum, brass, and hardened alloys. With threading tools, industries can achieve exact thread pitches, angles, and finishes that comply with global standards such as ISO, DIN, and ANSI.

Modern threading tools include single-point threading inserts, dies, taps, and thread mills, all optimized for different machining methods. Single-point threading inserts are widely used in CNC lathes, allowing flexibility in cutting metric, imperial, or custom thread profiles. Coatings such as TiCN and AlTiN extend tool life and enhance performance when cutting tough alloys. Thread mills, powered by CNC programs, enable multi-axis machining of threads with superior accuracy and reduced tool pressure, making them ideal for thin-walled components or hard materials. This technology provides industries with reliability and efficiency for high-volume production runs.

Applications of threading tools span multiple industries. In automotive manufacturing, threading tools are essential for creating threads in engine blocks, gear housings, and drive shafts. Oil & gas industries use them for threading large pipes and casings under high-pressure specifications. Aerospace relies on precision threading for fasteners in turbine assemblies and structural components. Even at the smaller scale, mechanical workshops and maintenance operations depend on threading tools for repairs, prototyping, and custom fabrication.

To maximize performance, tool material must be chosen based on the workpiece: HSS is cost-effective for general threading, cobalt HSS offers improved wear resistance for stainless steel, and carbide threading tools provide unmatched hardness for high-speed CNC machining. Proper alignment, lubrication, and cutting speeds further influence the quality of threads and tool longevity. These considerations are vital in Pakistan’s growing industries, where quality assurance and cost efficiency are top priorities.

ToolHoo.com offers an extensive selection of Threading Tools, from basic workshop dies and taps to advanced CNC threading inserts and mills. Our platform connects machinists, manufacturers, and engineers with globally trusted brands at competitive prices. Whether threading parts for heavy machinery in Lahore, repairing automotive components in Karachi, or fabricating aerospace structures in Islamabad, ToolHoo.com ensures you have the right threading solution. With nationwide delivery and expert guidance, we help industries achieve accuracy, reliability, and performance. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”