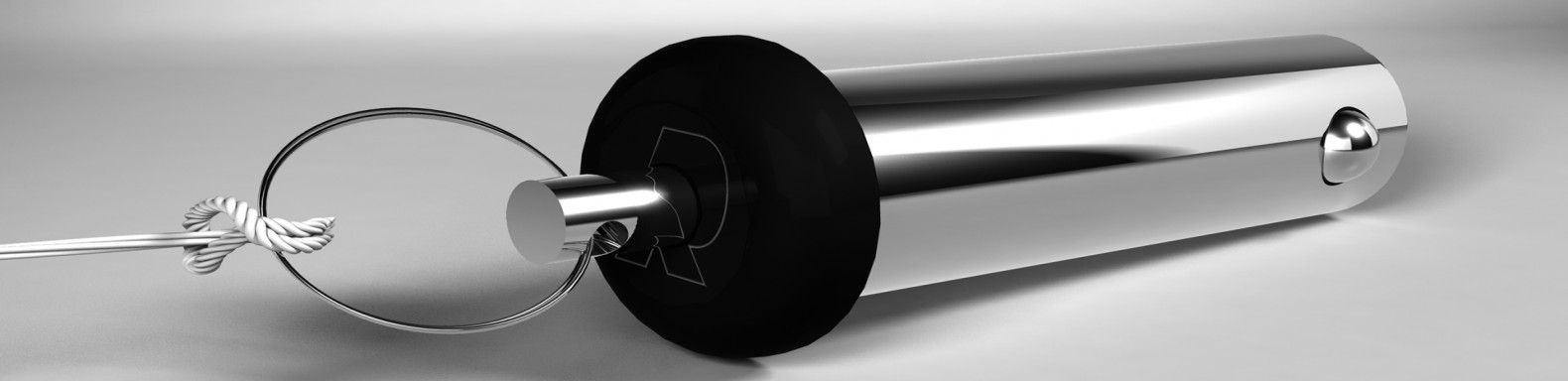

Quick-Release Pins

Quick-Release Pins are innovative fastening solutions designed for applications requiring frequent adjustments, removals, or repositioning. Featuring a push-button or ring-pull mechanism, these pins lock into place securely yet can be removed instantly without tools. Their design saves time and labor, especially in environments where speed and flexibility are essential.

Modern quick-release pins are made from stainless steel, carbon steel, and aerospace-grade alloys to ensure strength and corrosion resistance. They often include detent balls, locking rings, or button mechanisms for enhanced security. Variations include T-handle pins, ball-lock pins, and captive quick-release pins.

The major advantage of quick-release pins lies in their ability to combine strength with convenience. They eliminate the need for nuts, cotter pins, or threading, providing rapid yet reliable fastening in both light and heavy-duty applications.

Applications include aerospace equipment, marine hardware, industrial fixtures, sports equipment, and transport vehicles. In Pakistan, quick-release pins are common in construction scaffolding, heavy machinery maintenance, and defense equipment requiring rapid setup and disassembly.

Performance is influenced by material choice, locking mechanism quality, and proper pin sizing. Stainless steel is preferred in marine and outdoor environments, while alloy steel ensures superior load-bearing capability in industrial systems.

ToolHoo.com supplies a robust collection of quick-release pins for professional and industrial use. From Karachi’s shipyards to Lahore’s manufacturing plants, ToolHoo delivers fastening solutions that save time and increase reliability — “Tools No Toils – Solve IT!”