Grooving bars

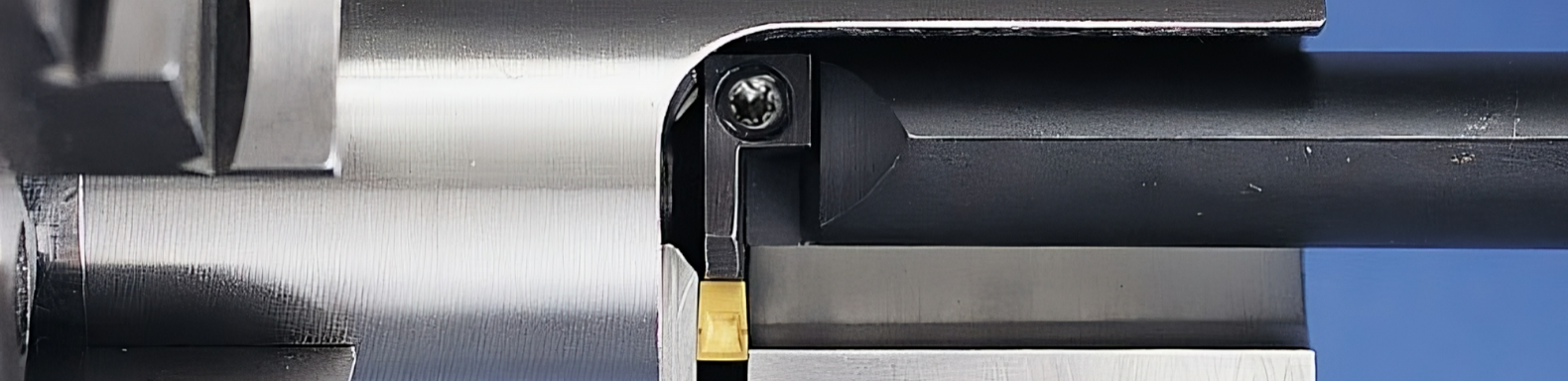

Grooving Bars are precision toolholders designed to cut internal or external grooves on workpieces during turning operations. They are an essential component of modern CNC and manual machining, supporting carbide or HSS inserts that create clean, accurate grooves for retaining rings, O-rings, or sealing applications. Available in a variety of shank sizes, lengths, and insert configurations, grooving bars deliver stability and rigidity, making them indispensable for tasks that demand precise depth and width control in grooving operations.

Modern grooving bars feature optimized geometries and internal coolant channels that improve chip evacuation and minimize tool wear. Carbide shank grooving bars offer high rigidity for deep cuts and hard-to-machine materials, while steel shank versions are more economical for general turning operations. Coatings such as AlTiN and TiCN enhance insert durability and performance, especially when working with heat-resistant alloys or stainless steels. These advancements ensure that grooving bars provide consistent results under high-speed and high-pressure machining conditions.

Applications of grooving bars are extensive. In automotive industries, they are used to machine grooves for piston rings, bearings, and shafts. In hydraulic and pneumatic systems, grooving bars create sealing grooves inside cylinders and valves. In aerospace manufacturing, they machine grooves in titanium and nickel alloys with tight tolerances for safety-critical components. Even in small workshops, grooving bars are essential for custom machining tasks, ensuring precise groove dimensions for reliable performance.

Selection depends on groove type (internal, external, face, or cut-off), material hardness, and machining environment. Proper clamping, cutting speeds, and lubrication significantly influence tool life and groove quality. For Pakistan’s industrial base, which spans from automotive workshops to aerospace facilities, grooving bars are vital in ensuring efficiency, precision, and repeatability in production.

ToolHoo.com offers a full range of Grooving Bars tailored for professional machinists and CNC operators. Whether you need economical solutions for a small workshop or advanced carbide bars for aerospace applications, ToolHoo.com delivers with consistency and reliability. With fast nationwide delivery and competitive pricing, we empower Pakistan’s industries to achieve flawless grooving results. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”