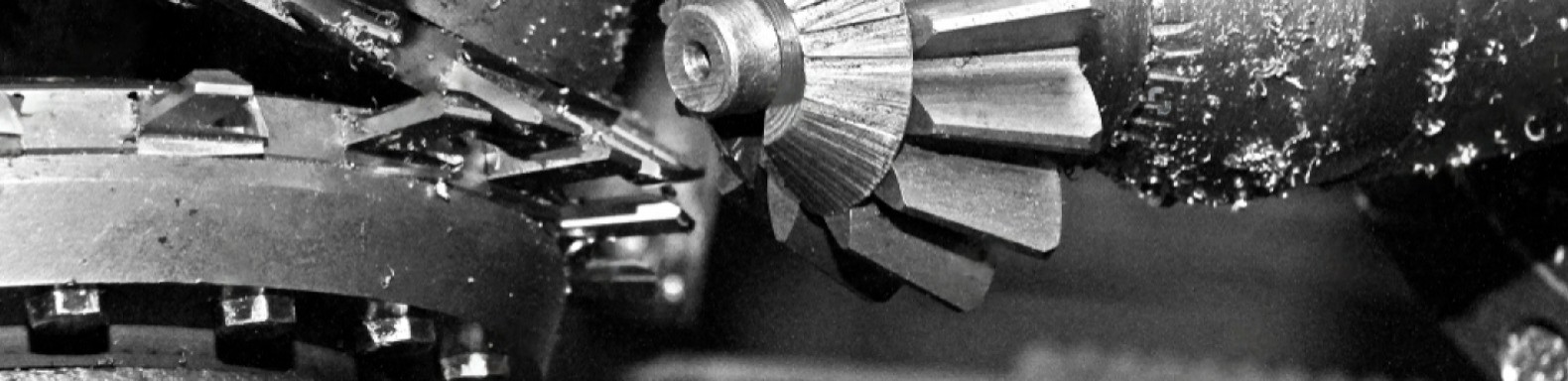

Single Angle Cutter

Single Angle Cutters are specialized milling tools designed to produce precise angled cuts, chamfers, and V-shaped profiles in metals, alloys, and composites. They are widely used in machining operations that require beveling, slotting, and angular shaping, making them essential in toolrooms, manufacturing plants, and precision engineering facilities. In Pakistan’s industrial sector, single angle cutters play a crucial role in preparing components for assembly and enhanci...

Modern single angle cutters are manufactured from High-Speed Steel (HSS) and solid carbide, with angles typically ranging from 30° to 60°. Depending on the application, they are produced in both right-hand and left-hand versions, with finely ground cutting edges to ensure burr-free machining. Advanced surface coatings such as Titanium Nitride (TiN) and Titanium Carbonitride (TiCN) enhance tool life, reduce wear, and improve cutting performance under high-speed conditions.

The applications of single angle cutters extend across gear manufacturing, aerospace machining, automotive production, and general engineering. In Pakistan, they are commonly used in machine shops for cutting precise keyways, chamfers, and grooves, while large industries rely on them for specialized machining operations on high-strength materials.

Performance depends on cutter geometry, spindle speed, and proper coolant usage. High-quality cutters ensure smooth surfaces, consistent accuracy, and longer tool life. When paired with CNC milling machines, single angle cutters deliver unmatched efficiency and repeatability in mass production environments.

ToolHoo.com offers a complete selection of Single Angle Cutters, from general-purpose HSS tools to advanced carbide solutions for CNC machining. With nationwide delivery, competitive pricing, and trusted global brands, ToolHoo.com ensures Pakistani machinists always achieve precision in angled cutting operations. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”