Setup & V-Blocks

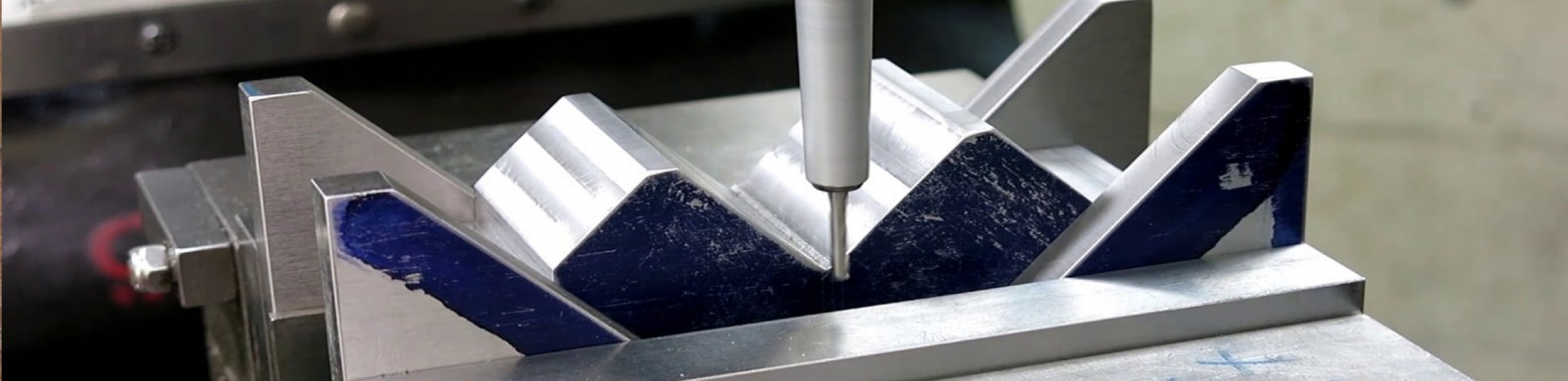

Setup & V-Blocks are precision workholding accessories used in machining, inspection, and assembly operations. Designed to securely position and support cylindrical or irregularly shaped workpieces, these blocks ensure stability and alignment during cutting, drilling, grinding, or measuring. By providing accurate support, setup blocks and V-blocks improve machining accuracy, reduce vibration, and protect delicate components from damage.

Types of setup tools include parallel blocks and 1-2-3 blocks used to raise or align workpieces, while V-blocks feature V-shaped grooves that cradle round parts for drilling or inspection. Magnetic V-blocks offer added holding power for ferrous materials, and clamping V-blocks provide secure fastening for heavy-duty machining. Hardened steel and precision-ground surfaces ensure durability and accuracy in demanding environments.

The applications of setup & V-blocks span machining centers, inspection labs, toolmaking, and fabrication workshops. In Pakistan, machinists rely on V-blocks for drilling holes in shafts, inspectors use them for dimensional checks, and workshops employ setup blocks to align workpieces on milling machines and surface grinders. Their versatility makes them essential for both routine and high-precision operations.

Performance and accuracy depend on block hardness, squareness, and surface finish. Precision-ground blocks minimize error, while clamping systems ensure repeatable setups. For Pakistani industries, setup and V-blocks provide cost-effective solutions that improve workflow and accuracy in competitive machining environments.

ToolHoo.com offers a full range of Setup & V-Blocks, from simple parallel sets to high-precision magnetic V-blocks. With durable construction, exact tolerances, and nationwide delivery, ToolHoo.com ensures machinists, inspectors, and engineers across Pakistan have the right tools to achieve consistent accuracy. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”