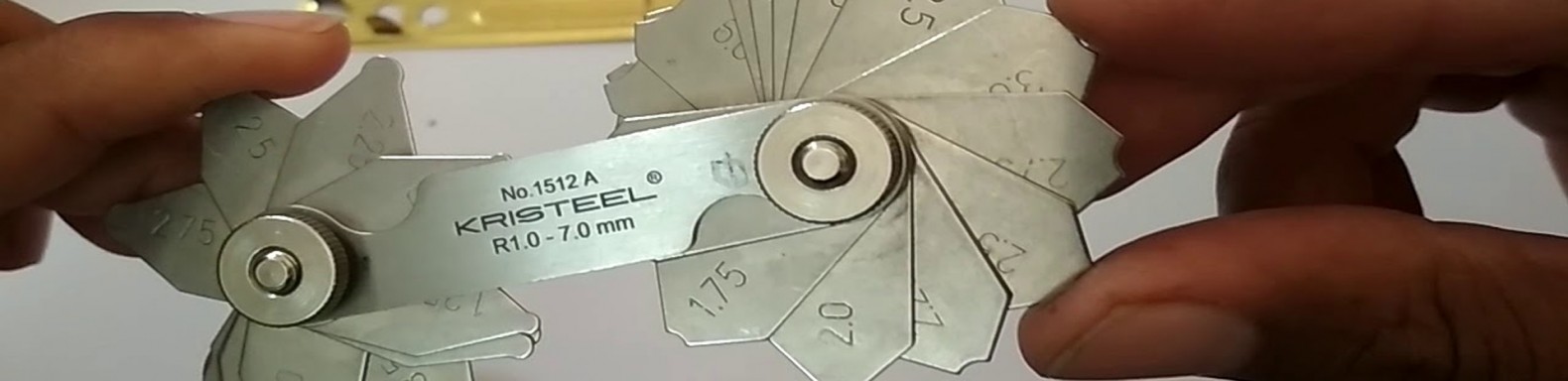

Radius gauges

Radius Gauges are precision measuring tools designed to verify the curvature of radii on machined parts, templates, and components. They consist of multiple blades, each with a different pre-machined radius, allowing quick comparison and inspection. By ensuring accuracy in curves and contours, radius gauges are vital in machining, toolmaking, automotive design, and quality control processes where even small deviations in curvature can compromise functionality or assembly.

Types of radius gauges include concave gauges for checking external radii, convex gauges for measuring internal curves, and combination sets that offer both functions. These gauges are typically made of hardened stainless steel for durability and precision, with clearly etched markings for quick identification. Some advanced models include locking devices to hold blades in place, ensuring stable measurement during inspection.

The applications of radius gauges extend across machining centers, automotive workshops, fabrication plants, and tool inspection labs. In Pakistan, machinists use them to confirm tool profiles, die makers employ them in mold making, and quality inspectors rely on them to verify part compliance with design specifications. Their simplicity and reliability make them an essential addition to any precision workshop.

Performance and accuracy depend on blade quality, surface finish, and proper usage. Regular cleaning and storage in protective cases ensure long-lasting accuracy. For Pakistani industries where dimensional precision is key, radius gauges provide a cost-effective, dependable solution for quality assurance.

ToolHoo.com supplies a wide range of Radius Gauges, from compact workshop sets to high-precision industrial models. With nationwide delivery, affordable pricing, and trusted quality, ToolHoo.com ensures machinists, engineers, and inspectors across Pakistan can measure curves with confidence. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”