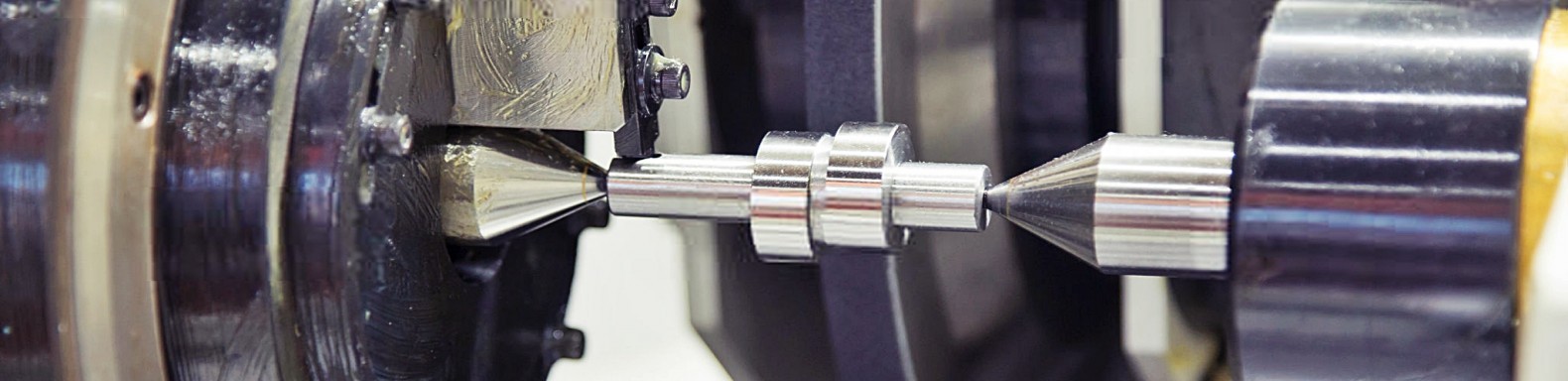

Live & Dead Center

Live and Dead Centers are lathe accessories used to support long workpieces during turning operations, ensuring stability, concentricity, and vibration-free machining. Mounted in the tailstock, these centers prevent deflection while the workpiece rotates, enabling accurate turning of shafts, spindles, and cylindrical parts. For industries across Pakistan, especially in automotive, aerospace, and heavy engineering, the use of live and dead centers is critical to achieving tight ...

Dead centers are hardened steel tools with a pointed tip that remain stationary while the workpiece rotates against them, ideal for slower-speed operations and grinding. Live centers, by contrast, incorporate high-precision bearings that rotate with the workpiece, reducing friction and heat build-up, making them suitable for high-speed turning. Variations include bull nose centers for pipes, half centers for clearance in facing, and carbide-tipped centers for hard materials.

Applications in Pakistan include textile machinery workshops in Faisalabad where long shafts are turned, automotive factories in Karachi that machine crankshafts and axles, and aerospace facilities in Lahore requiring precision support for titanium and alloy components. The proper use of centers prevents runout, ensures accuracy, and extends the life of both the cutting tool and workpiece.

ToolHoo.com supplies a wide variety of Live and Dead Centers, including general-purpose, heavy-duty, and carbide-tipped designs. Our centers deliver durability, precision, and smooth operation, making them ideal for workshops and industries across Pakistan. With fast delivery and expert support, ToolHoo.com ensures machinists always have reliable support for precision turning operations.