Combined Drill Taps

Combined Drill Taps are multifunctional cutting tools that perform both drilling and tapping operations in a single step, saving time and improving efficiency. By drilling a hole and immediately forming threads, these tools eliminate the need for tool changes, making them ideal for high-speed production and workshop use. In Pakistan, combined drill taps are highly valued in CNC machining, automotive workshops, and metal fabrication industries.

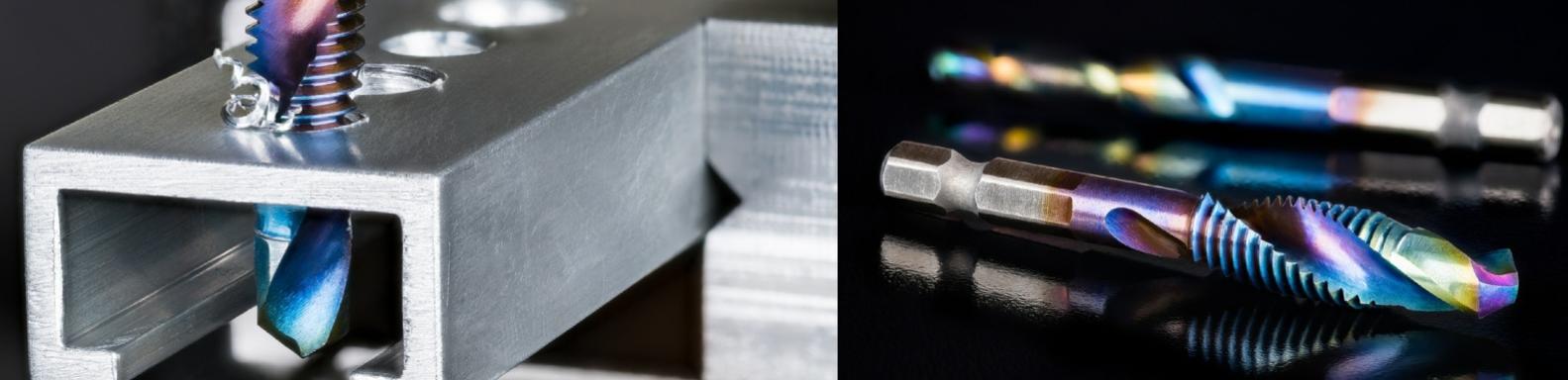

This category includes spiral point drill taps for through holes, spiral flute drill taps for blind holes, and straight flute versions for general-purpose applications. Made from high-speed steel, cobalt steel, or carbide, combined drill taps are often coated with Titanium Nitride (TiN) or TiCN to increase wear resistance and extend tool life in high-speed operations.

The applications of combined drill taps in Pakistan are extensive. Automotive manufacturers in Lahore use them for engine and chassis components. Construction workshops in Karachi employ them for steel framework and assembly work. Industrial CNC shops in Faisalabad use combined drill taps for efficient production of threaded holes in aluminum, mild steel, and stainless steel. Even small-scale workshops benefit from reduced tool change times and improved productivity.

Performance depends on material compatibility, flute design, and proper lubrication. When used correctly, combined drill taps ensure accurate hole sizes and precise threads while reducing cycle times. In Pakistan’s growing industrial sector, these tools are essential for competitive, high-speed manufacturing.

ToolHoo.com offers a complete range of Combined Drill Taps, from general-purpose tools to high-performance CNC-grade options. With expert advice, nationwide delivery, and competitive pricing, ToolHoo.com ensures Pakistan’s industries and workshops achieve efficiency and accuracy in threading operations. At ToolHoo.com, it’s always “Tools No Toils – Solve IT!”